What's the difference between TFT, LCD, and OLED displays? And when does it matter in product design?

Let’s be (ahem) clear: TFTs, or thin film transistors, are a type of LCD. But they have unique properties that make them stand out when sourcing display modules.

LCDs, or liquid crystal displays, utilize liquid crystal molecules sandwiched between two polarizing filters. When an electric current is applied, the liquid crystals align to control the passage of light, creating images on the screen.

TFT displays on the other hand are LCDs that use thin-film transistors to control individual pixels. Each pixel consists of a liquid crystal element and a corresponding thin-film transistor, allowing for precise control of brightness and color. TFTs are usually in RGB color and are passive, so they need a backlight, often provided by LED.

OLED (organic light-emitting diode) displays by contrast use organic compounds that emit light when an electric current passes through them. Unlike LCDs, OLEDs do not require a backlight, as each pixel emits its own light independently.

Comparative Advantages and Design Considerations

Designing with LCD

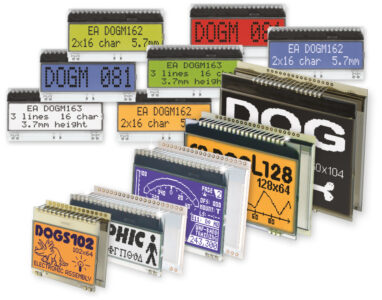

LCDs are a mature technology with widespread adoption, making them cost-effective for mass production. They come in a wide variety of sizes and resolutions and are suitable for outdoor applications due to their capacity for high brightness.

Contrast ratios in LCDs may be limited compared to OLED displays, however, and viewing angles may be narrower compared to either OLED or TFT displays, especially in older LCD panels. Because backlighting is necessary, energy consumption increases, design profiles run a bit thicker, and there is potential for uneven lighting. Overall, though, they consume little energy.

LCDs can also reflect incidental light and are therefore legible even at maximum brightness, as with sunlight or surgical lighting. Compared to TFT and OLED, they have an unbeatable advantage in terms of readability and power consumption.

Sometimes LCDs consume even less than an e-paper display. In static an e-paper display operation requires absolutely no energy to maintain its content. To change content, however, a large amount of power is needed.

As a rule of thumb for HMI design, sunlight = LCD.

Designing with TFT

TFTs are known for their vivid colors, high resolution, and wide viewing angles. They have extremely fast response times and are suitable for video, with no motion blur or ghosting. TFT displays can be manufactured in larger sizes and support integration with touch functionality.

The main design considerations for TFTs involve their backlighting requirement (see above).

Designing with OLED

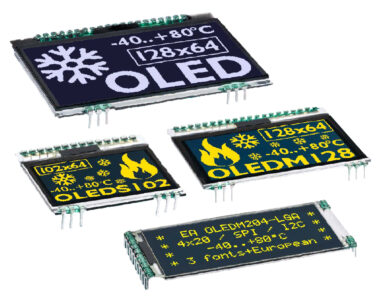

OLED displays offer exceptional contrast ratios and deep blacks, as individual pixels can be turned off completely. As with TFTs, they boast wide viewing angles with consistent color accuracy.

They are also thinner and lighter than LCD and TFT displays, as no backlight is needed. Best of all, they boast exceedingly fast response times. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz—an advantage in special applications.

OLEDs technically consume less power than both, though this is dependent on the content displayed, and since the efficiency of converting electric current into light energy is still poor, the power consumption of an OLED is generally higher than a TFT of comparable size.

Note that OLEDs are not as bright as LCD or TFT displays in outdoor environments with direct sunlight. And while the technology is improving, the organic materials degrade and are susceptible to burn-in, particularly with static images displayed for extended periods. For this reason, the OLED displays used for industrial and medical applications are typically monochrome (usually yellow).

Choosing the Right Display Module for Industrial and Medical Applications

Obviously, the popularity of a particular kind of display module in the consumer market should have little to no bearing on an engineer’s choice of display module for other applications and markets. What ultimately matters are one’s own design requirements and constraints.

Be aware of how your supplier manages quality assurance and product development, as this will be an indication of a manufacturer that you can rely on.

Between LCD, TFT, and OLED, there is no “best” solution for all applications; there are pros and cons to each. In addition to the differences outlined above, there are many more details in the design and construction that need to be individually (ahem) illuminated for each device.