This website uses cookies for analytics, personalization, and other purposes. By continuing to browse, you agree to our use of cookies as described in our Cookies Statement. View our privacy policy to learn more.

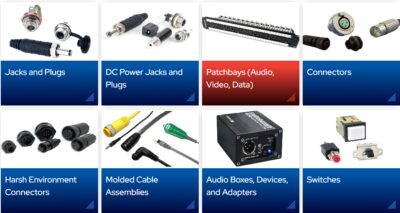

Harsh Environment Connectors, Jacks, Plugs, Audio Connectors, Custom Molded Cable Assemblies & General Purpose Switches.

Made in USA.

Switchcraft® Conxall® builds nearly all of our products in the USA. We are highly vertically integrated, and most of our suppliers are also US-based. We are ready to work with you to reduce your costs and simplify your supply chain.

Switchcraft is a leading supplier of a broad line of components for the audio, video, telecommunication, computer, medical, military, appliance, transportation and instrumentation industries. With a basic line of over 5,000 standard products and thousands of variations, Switchcraft markets products both domestically and internationally through a network of manufacturers' representatives and independent distributors.

We specialize in quick-turn, low-volume, custom-engineered harsh environment products using our round, sealed connectors. With a on-site toolroom and 3D design capability, we can provide the fastest, most efficient response for all your project's custom needs.

Switchcraft® designs have become industry standards... and for good reason. Our designs provide effective, reliable solutions in a variety of applications. If you can't find exactly what you need from our vast array of product offerings, our engineering staff will work with you to build a custom product to meet your requirements. Effective communication between our engineers and our customers throughout the design phase, is critical for success. We listen and we respond. Advanced CAD capabilities enable Switchcraft engineers to create 3-dimensional solid models, as well as SLA and SLS prototypes. Our model shop boasts molding, milling and drilling machines, grinders, saws, and lathes for prompt prototyping. Innovation in design, creative use of materials, and CNC/EDM capabilities including prototype tooling, combine to make Switchcraft® products unique. Once the design is approved, we can move directly from CAD right to manufacturing, shortening the production cycle and ensuring the integrity of the design. Extensive in-house testing facilities provide quick, accurate results. Our environmental test lab is equipped to analyze and measure salt spray and humidity resistance, life cycle, compatibility with military and commercial parameters, tensile strength, Hi-pot testing, shock and vibration. Our talented staff of engineers has an intimate understanding of the latest in engineered materials to creatively design and select the right one for the job.

Just as the quality of your product depends on the quality of the components inside, Switchcraft® quality components begin with quality piece parts. As a vertically-integrated company, we produce most of the components we use in-house to control quality and delivery. We constantly evaluate and amend our select list of certified suppliers, based upon their ability to consistently deliver quality, value and service to meet our requirements. We hold our suppliers to the same stringent standards we have set for ourselves: our suppliers must be as responsive to our needs as we are to yours.

Molding, stamping, plating, machining, and assembly are done in the United States, specifically at our 185,000 square foot Chicago facility. The benefit: Switchcraft is able to maintain strict control over production and quality. A second manufacturing facility in Inchon, Republic of South Korea supports customers in the Far East. An increasing number of our molds and dies are built and maintained in-house. Using Statistical Process Control standards, we monitor and maintain consistent manufacturing performance. The perfect blend of top notch equipment, streamlined production procedures and the dedication of our experienced, talented personnel is reflected in each and every product we manufacture...each and every time. Whether the components are fully automated, semi-automated or hand-assembled in Chicago or Inchon - attention to detail at every stage results in characteristic Switchcraft® excellence.

As a global-minded U.S. manufacturer, Switchcraft builds and tests products to meet the demands of worldwide approval agencies including UL, CSA, VDE, Semko, Demko, Nemko, SETI, SEV, Mil-Spec and IP68. A network of international distributors market our products worldwide.

Switchcraft Conxall Technical White Papers and Resources

Top Technical White Papers:

Supporting Documentation:

Search authorized distributors on trustedparts.com. Select the manufacturer name or type into search bar.